Products >> Plastics testing machine >>

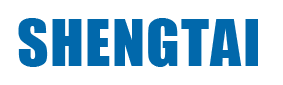

Weights auto loading melt flow rate index tester MFR MVR Double Test

- Product No.:202372111586

Weights auto loading melt flow rate index tester MFR MVR Double Test Specification

It is used to determine the melt flow rate MFR and MVR value of various plastics and resins passing through a certain temperature and load in a viscous state through a standard die every 10 minutes. It is suitable for polycarbonates, polysulfones, fluorine with higher

melting temperatures Engineering plastics such as plastic and nylon are also suitable for polyethylene (PE), polystyrene (PS),

polypropylene (PP), ABS resin, polyoxymethylene (POM), polycarbonate (PC) resin, etc. The plastic testing is widely used in

plastic production, plastic products, petrochemical and other industries, as well as relevant institutions, scientific research

units and commodity inspection departments.

Price Plastic Melt flow Index Tester, Laboratory MFR MVR Double Test Melt Flow Indexer Price

melting temperatures Engineering plastics such as plastic and nylon are also suitable for polyethylene (PE), polystyrene (PS),

polypropylene (PP), ABS resin, polyoxymethylene (POM), polycarbonate (PC) resin, etc. The plastic testing is widely used in

plastic production, plastic products, petrochemical and other industries, as well as relevant institutions, scientific research

units and commodity inspection departments.

Meeting standards

ISO 1133: 1997 "Determination of the melt mass flow rate MFR and the melt volume flow rate MVR of thermoplastics"

ASTM D1238 Standard Test Method for Melt Flow Rate of Thermoplastics by Extrusion Plasticity Meter

ASTM D1238 Standard Test Method for Melt Flow Rate of Thermoplastics by Extrusion Plasticity Meter

Features:

1.The results can be automatically calculated for mvr test method, which has the function of electrically automatic loading weights. The machine also has function of timing, cutting, loading, printing.

2.Computer Control software can achieve the setting of the parameters, temperature control, cutting, measurement calibration,

automatic loading weights, timing, MFR and MVR results showing, downloaded test data;

2.Computer Control software can achieve the setting of the parameters, temperature control, cutting, measurement calibration,

automatic loading weights, timing, MFR and MVR results showing, downloaded test data;

To prevent incorrect operation, part of the important operation need to use password authentication.

3.7 inch full color touch screen,English language interface.

4. The heating rate is fast, and the temperature can be quickly restored after

the filling. Has the upper limit temperature protection, constant temperature sound prompt, reply time sound prompt and so on

5.In the interface, customer can choose test standard ASTM standard, ISO standard, etc.

6.The software can save eight groups test results one time.

7.The maximum temperature is up to 450~500 degrees (especially for corrosive material and fluoride plastic and the function is optional)

3.7 inch full color touch screen,English language interface.

4. The heating rate is fast, and the temperature can be quickly restored after

the filling. Has the upper limit temperature protection, constant temperature sound prompt, reply time sound prompt and so on

5.In the interface, customer can choose test standard ASTM standard, ISO standard, etc.

6.The software can save eight groups test results one time.

7.The maximum temperature is up to 450~500 degrees (especially for corrosive material and fluoride plastic and the function is optional)

Previous Product:Izod pendulum impact testing machine

Next Product:Digital Melt flow index rate tester plastometer with mini printer

Products Category

Contact Us

Name: Anne Liang

Tel: +86-13592713824

E-mail: annelyno@163.com

WeChat: Annefa1156

Add: One building, 8 zhuzhong road, Houjie Town, Dongguan City

CHINESE

CHINESE ENGLISH

ENGLISH

Mail inquiry

Mail inquiry